EXPERIENCE

The ProPulse Difference

We offer the right balance of technical excellence, industry knowledge, and flexibility to make incredible improvements to a wide range of markets.

Our team is comprised of bright technical experts who are ready to help you solve tough problems.

We are large enough to be a leader in the fluid power industry but small enough to be responsive, proactive, and fast on our feet. By embracing change and innovation, we craft individualized products and solutions specific to your needs.

We live for this—and you’ll be glad—because we will help you get the right hose with optimal fit, form, and function.

Controlled Performance

On-time delivery and quality are automatic when information, documents and processes are controlled.

Increased Longevity

Longevity isn’t just company history—it’s about knowing industry trends and where our business is headed.

Technical Excellence

Engineering, prototyping, manufacturing and assembling hoses is the main wheelhouse of expertise.

Continuous Improvement

On-time delivery and quality are automatic when information, documents and processes are controlled.

Powerful Partnerships

Support specialists and technical experts are readily available to provide knowledge and assistance when you need it.

QUALITY & PERFORMANCE

Quality Assurance

On-time delivery and quality are automatic when information, documents and processes are controlled.

More often than not, it’s the hose that makes or breaks that end goal. Yet sometimes, the hose doesn’t get the respect it deserves. It does at ProPulse. We have devoted significant time and brainpower to controlled performance resulting in a series of policies, procedures, technologies, and tests with the highest level of quality and performance for our high-pressure hoses.

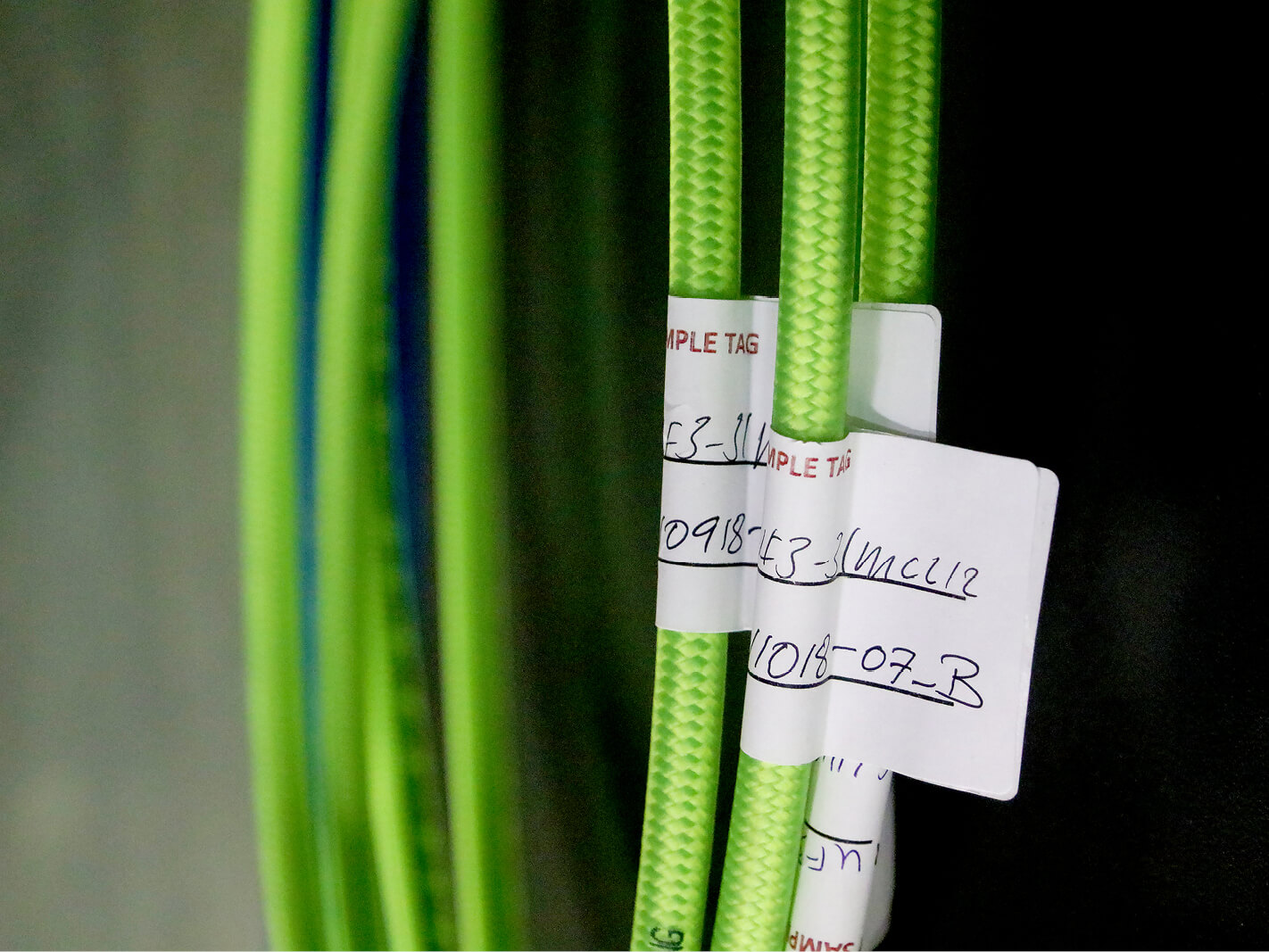

Allowing for easier tracking and replacement, lot and batch traceability are built into our manufacturing process of every single hose. Our proprietary PLC-controlled automatic assembly lines and crimping technology are the most innovative and advanced machinery in North America; they support the low cost of throughput with very high-quality results.

Beyond that, day in and day out, we are continually monitoring, documenting, and controlling every aspect of the manufacturing, and assembly process. ProPulse has maintained 100% on-time delivery for more than 3 years.

ProPulse is ISO 9001:2015 Certified

ISO 9001:2015 certification provides us the ability to enact growth, profitability as well as cost savings.

Receiving Inspection

We rigorously vet all suppliers.

Outside suppliers are subject to stringent visits and on-site visits. All incoming shipments are counted, verified, inspected, and documented by in-house quality assurance technicians.

Hose Lot Testing

Every lot of hose manufactured is inspected, tested and recorded.

Quality assurance technicians perform elongation, burst, and leak tests to verify the hose is made to spec. In addition, technicians will diligently inspect the cover, layline, OD, ID, and concentricity to ensure the highest level of quality.

In-Process Auditing

Each work ticket requires first piece inspection.

During assembly, each work ticket requires first piece inspection, validation, and approval before production can continue. Qualified personnel inspect the date stamp, crimp specs, and hose length. Beyond that, technicians continually conduct out-of-box audits.

Packaging Verification

After a box of assemblies has been packaged, box quantities, placards, labels, ties, and overall condition are inspected by job title will go here and must be approved before advancing to the loading dock.

WHERE WE ARE HEADED

Past. Present. Power Moving Forward.

Longevity isn’t just company history—it’s about being industry specific and knowing where our business is headed.

ProPulse—a Schieffer Company is backed by nearly a century of innovative and precise German design and engineering. We partner with vendors and OEMs from across the globe and network in diverse market groups.

We have done a comprehensive analysis of the high-pressure hose market and identified your company as a leader among your peers. We know that what you do dovetails with our core strengths. We can’t say that about every company, and frankly, we don’t sell to just anyone. We are quiet confident that what we do is better than anyone else who supports production lines with concentrations of high volume, small bore hoses.

Today, ProPulse is successful and growing, having doubled in the last five years. Our management team is focused on a detailed strategic planning process that considers and addresses both the internal and external factors and conditions that affect the business. Most recently, we invested in a new building with office space, warehousing and land for further expansion. Additional equipment was also purchased to increase manufacturing hose capacity by another 50%.

We work closely with customers to bring the best innovative products to the marketplace by:

Always focusing on customer satisfaction and success

Continuously improving products and productivity for the entire life cycle of the products

Responding rapidly to changing customer needs and market demands

Continually working to reduce total cost while maintaining top quality and performance

Working together to help each other take advantage of growth opportunities

PROCESS CAPABILITIES

Shaped For Your Business.

Custom Hoses Engineered For Your Industry.

Let us take you on a power trip—our facility, technical excellence and equipment are state of the art.

Two decades of partnering with numerous worldwide OEM’s has built the foundation for our business ethics and experience. ProPulse consistently fulfills strict quality and delivery requirements, because we can handle the pressure.

Our team of qualified specialists delivers above industry standards. This wealth of experience is reflected in our commitment to quality, reputation for technical excellence as well as our integrity & business ethics.

Our manufacturing capabilities have a reputation for unsurpassed turn-around time; engineering, design and development; and prototype assemblies to help get projects off the ground quickly. 99.99% on-time delivery doesn’t happen by accident. Sustaining that rate for over 3 years is technical excellence.

ProPulse's in-house testing capabilities account for every dynamic test within SAE and EN norms.

Our evaluations focus on simulating environmental concerns to see how hose assemblies will perform under different types of stress. We recently invested heavily in the infrastructure and capital equipment needed to help OEM customers reduce downtime, increasing safety and reducing costly damages from failures is priority. Consistent testing and retesting, in conjunction with audits and ISO 9001:2015 certification, assures the quality of our operation and products.

Heat Shrink Capping Technology

We use heat shrink technology to securely seal the ends of your hydraulic hose assemblies, providing a superior alternative to traditional caps and plugs. The seal cap uses a tear strip that can be removed in just seconds. This improves the customer’s speed of assembly and further mitigates the risk of contamination by keeping the hose covered until the exact moment of installation.

Spectro Technology

We use spectro technology to measure reflected or transmitted light at many points on the visual spectrum, which results in a curve. Since the curve of each color is as unique as a finger print, it is the optimal tool for identifying, specifying and matching exact pantone colors for branding purposes.

Crimping Technology

Our proprietary PLC controlled automatic assembly lines and crimping technology are the most innovative and advanced machinery in North America; we support the low cost of throughput with very high-quality results.

PRODUCT DEVELOPMENT

Custom Hose Solutions

All products can be improved.

We’ll help you be better at any stage, whether you choose to engage us early in product ideation sessions, in design review and feasibility or in prototyping and packaging development. Our experienced team can help with materials specification, streamlining process development and other steps to evolve your product toward market.

Research & Strategic Planning

We can help you factor product viability, intellectual property, risk management, strategic sourcing and target cost management in your early-stage product development.

Design & Development

Assessing manufacturability of your design, materials and processes, our team members can help you with design enhancement recommendations and iterative development stages.

Prototyping

We are equipped with the knowledge, processes and facilities to help you with product validation and proof-of-concept evaluation samples, supporting clinical trials and other approval stages – all produced with environmental clean-room and dry-room controls to assure quality.

ISO 9001:2015

We offer quality audits, testing and documentation, in an ISO 9001:2015 facility, offering labeling and traceability with strict lot controls.

Packaging & Distribution

Beyond the converting, production and semi-automated assembly of your product, we can help with package design, in-line pouching and printing, as well as planning and managing contracted services, such as sterilization, logistics and freight.

Full PPAP Capabilities

We can help you factor product viability, intellectual property, risk management, strategic sourcing and target cost management in your early-stage product development.

MANUFACTURING CAPABILITIES

Power Up With ProPulse

Optimized Capacity. Technical Excellence. Powerful Results.

We are a vertically integrated thermoplastic hose manufacturing company that has served the hydraulic industry for more than 25 years, first as a distributor and then as a manufacturer. Almost ½ of what we manufacture are customized solutions. Engineering, prototyping, manufacturing and assembling hoses is the main wheelhouse of expertise.

Manual Assembly

Automatic Assembly

Extrusion & Braiding

Warehouse

Shipping & Receiving

New Facility

Continuous Improvement Taken Seriously

It's not just an ISO requirement—at ProPulse, iT's a responsibility.

It is ProPulse’s mission to build a company through the unified pursuit of sustainable growth and value. This means never being content with operational performance, because at ProPulse we are always striving for better.

Each day, we work on continually improving as individuals, a team and as a company.

This is possible through clear, cohesive planning and organizational alignment.

The result is a well-run high-pressure hose manufacturer with innovative methods of communicating with customers. This ensures customer requirements are determined and met with the aim of enhancing customer satisfaction.

Continuous Improvement

ProPulse is consistently improving. We believe that there is always an opportunity for us to meet our customers’ needs better.

In a world where OEM’s needs are continuously changing, we are dedicated to advancing our manufacturing process. If there is a better, faster, or smarter way to do things, you can trust ProPulse will find it.

Consistent 99.99% On-Time Delivery

While other suppliers may have issues sourcing their products, we manufacture all of our thermoplastic hoses in house and have the capacity to meet your requirements.

Minimize Scrap

ProPulse continues to minimize the amount of scrap and waste from our hose production.

Doubled in Size & Still Growing

We have grown our employee base from six to 126. In the last five years we have doubled in size and we predict to continue this growth into the future.

Encourage Employee Growth

We value our team, which is why we encourage our employees to improve their skills while supplying them with the tools necessary to grow from their current role.

Investment in New Technology

ProPulse understands the importance of innovation, so we invest in new manufacturing solutions to build a better hose.

Expansion of Facilities

Because of our rapid growth, we have purchased an additional building and expanded our manufacturing facility in order to meet the needs of our customers and our employees.

PARTNERING WITH PROPULSE

Choose a Partner, Not a Vendor.

We create synergy within the supply chain—to form win-win partnerships.

At ProPulse, we have been delivering results, reliability, and rock-solid relationships for more than 20 years. We partner with numerous OEM’s and distributors, to provide them with everything they need to succeed. With you in mind, customer service specialists and technical product experts are readily available to provide knowledge and assistance when you need it most. Because we know that line down is not an option.

We will work with you to find the best solutions, as well as the right high-pressure hose for your specific application. We will even come on-site to help with design and routing.

At ProPulse, we go beyond the traditional customer-vendor relationship and work hand-in-hand with our customers to execute their vision.

Information Sharing

We believe in openness and honesty. We initiate communication of accurate information and openly share ideas and resources to support continuous improvement.

Responsiveness & Problem Resolution

We proactively initiate resolution and implement corrective action as quickly as possible.

Business Partnership

At ProPulse, we develop mutually beneficial and profitable partnerships with customers, allowing success in the marketplace that is aligned with our mission, vision, and values.

We work best when we work alongside customers, seeing how the products are used every day and what issues are faced. We are the self-proclaimed “geek” of the high-pressure hose world. And that is all good news for you.

Standing Behind a Hose Partner with Power.

Nobody does more to ensure the success of their OEMs and distributors than ProPulse. Just ask our long-time partner Ultimate Washer.

What does the “ProPulse Difference” mean to you?

Our successful business partnership was built on trust, loyalty and superior quality products. And in the rare instance any issue occurs, your team of experts is readily available, attentive and reactive to our specific needs. Always.

What specific issues did you encounter before partnering with ProPulse?

Prior to ProPulse, there was simply no sense of urgency from our vendor when it came to daily communication, to quotes or resolution of issues.

Why does Ultimate Washer partner with ProPulse?

Not only is the pricing fair, but the customer support and product quality are next to none. ProPulse helped us ramp up and cultivate better business, ultimately resulting in more sales and profits.

LET’S FIND YOUR SOLUTION!

Get in touch with one of our experts.

We can help with your custom hose requirements.