CONTROLLED PERFORMANCE IN HOSE MANUFACTURING

DEPENDABLE HIGH-PRESSURE HOSE ASSEMBLIES

QUALITY & PERFORMANCE

Quality Assurance

On-time delivery and quality are automatic when information, documents and processes are controlled.

More often than not, it’s the hose that makes or breaks that end goal. Yet sometimes, the hose doesn’t get the respect it deserves. It does at ProPulse. We have devoted significant time and brainpower to controlled performance resulting in a series of policies, procedures, technologies, and tests with the highest level of quality and performance for our high-pressure hoses.

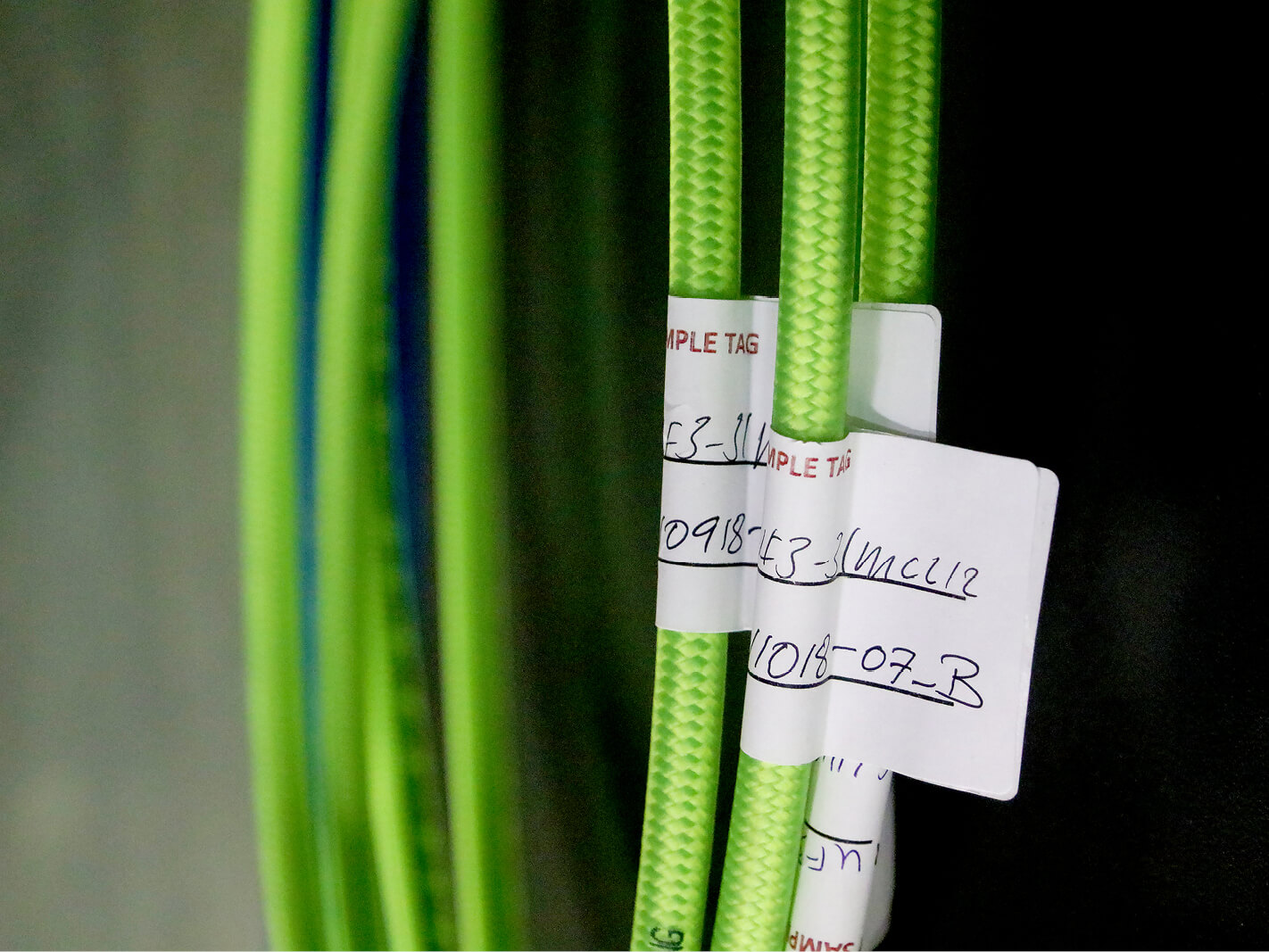

Allowing for easier tracking and replacement, lot and batch traceability are built into our manufacturing process of every single hose. Our proprietary PLC-controlled automatic assembly lines and crimping technology are the most innovative and advanced machinery in North America; they support the low cost of throughput with very high-quality results.

Beyond that, day in and day out, we are continually monitoring, documenting, and controlling every aspect of the manufacturing, and assembly process. Our on-time delivery is at a sustained success rate of 99.99% for two years in a row.

ProPulse is ISO 9001:2015 Certified

ISO 9001:2015 certification provides us the ability to enact growth, profitability as well as cost savings.

Receiving Inspection

We rigorously vet all suppliers.

Outside suppliers are subject to stringent visits and on-site visits. All incoming shipments are counted, verified, inspected, and documented by in-house quality assurance technicians.

Hose Lot Testing

Every lot of hose manufactured is inspected, tested and recorded.

Quality assurance technicians perform elongation, burst, and leak tests to verify the hose is made to spec. In addition, technicians will diligently inspect the cover, layline, OD, ID, and concentricity to ensure the highest level of quality.

In-Process Auditing

Each work ticket requires first piece inspection

During assembly, each work ticket requires first piece inspection, validation, and approval before production can continue. Qualified personnel inspect the date stamp, crimp specs, and hose length. Beyond that, technicians continually conduct out-of-box audits.

Packaging Verification

After a box of assemblies has been packaged, box quantities, placards, labels, ties, and overall condition are inspected by job title will go here and must be approved before advancing to the loading dock.