The manufacturing industry is challenged with producing goods more efficiently and sustainably.

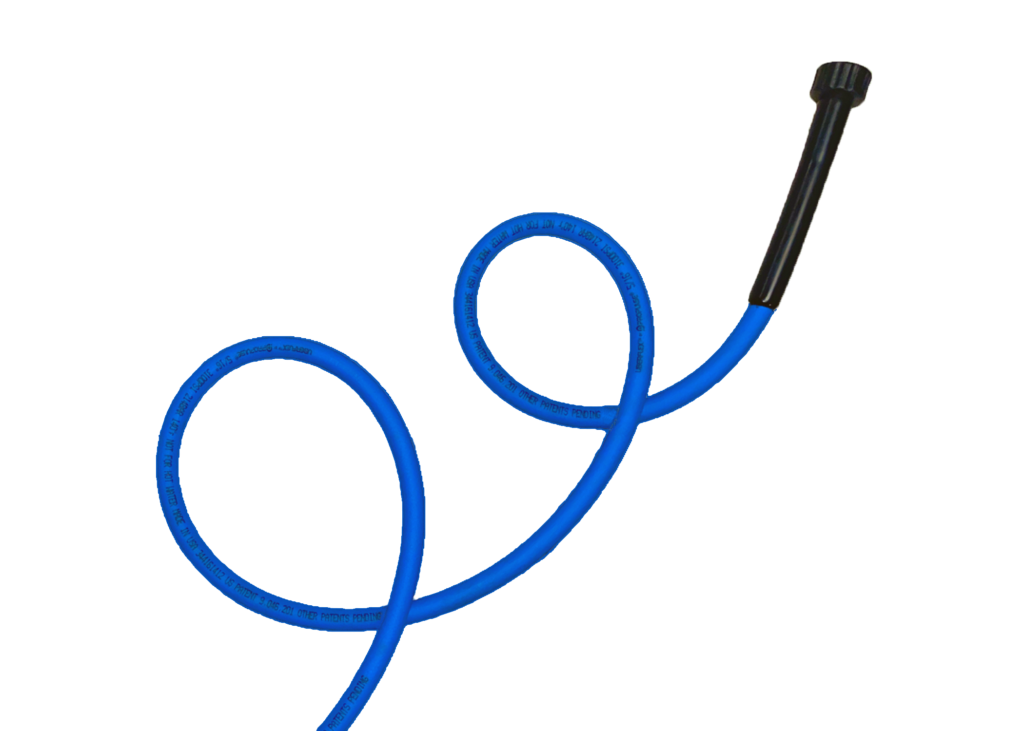

As a U.S. manufacturer of high-pressure hoses, ProPulse aims to limit the waste made from producing and sourcing hydraulic and pressure washing hoses. We are committed to producing quality hose with limited impact to our surrounding community and environment.

Purposeful Changes

Depending on the manufacturing process, procedures can be inefficient and produce unnecessary waste. At ProPulse, we have reimagined several areas of our manufacturing facility, to ensure efficiency.

Sourcing engery from manufacturing

Our manufacturing plant is

climate controlled for our employees. To cut down on our energy consumption, we

reuse and source energy from some of our manufacturing processes. In the

wintertime we use the heat produced from our energy efficient dryers to keep

the building warm, and we can redirect it outside during the summer to reduce

our dependence on our air conditioning units.

We plan to switch over to a smart

thermostat, to help reduce energy waste by regulating the temperatures inside

our facilities.

reduce water consumption

In our extrusion process we use water to cool the recently formed thermoplastic hose. With our new extrusion lines, we can reuse this water to avoid waste, while maintaining our high-quality.

efficient lighting

All of the lighting in our facilities are LED, which can reduce energy waste in comparison to traditional lighting. We utilize automatic light sensors throughout the plant as well to reduce unnecessary energy waste. We also installed solar lighting to our overhead lights in the parking lot to supply cleaner energy lighting for our second and third shift employees.

paperless departments

Inside our office space, we are also remaining vigilant on our consumption. Recently our maintenance team and quality departments have switched to a 100% paperless reporting procedure. This has reduced our paper usage by an estimated 250 pages a week – that’s a lot of ink!

Future

ProPulse is constantly growing. Several departments track and analyze our waste and performance data to help us continue to grow sustainably. Many of our departments analyze efficiency, and in most cases, waste weighs on efficiency and slows down productivity.

Ultimately green technology still has a long way to go. And while our main focus is to deliver high-quality products to our customers, we keep in mind the impact we have on our community. That’s why everyday we try to improve, even in the smallest ways, because we know that small things can have great impacts, especially when it comes to manufacturing.

Continuous Improvements

At ProPulse we are always trying

to improve. From our relationships with our customers, to our production

processes, we believe in sustainable improvement through all of the aspects of

our business. Whether that is adding solar to our parking lot lighting or

choosing to market via email vs mail. We

will continue to power moving forward, sustainably.

About ProPulse

ProPulse is an Iowa-based hose manufacturer that assembles thermoplastic and wire braided rubber pressure washer and hydraulic hose assemblies. Founded in 1998, ProPulse specializes in supplying OEM production lines for world class companies that manufacture machinery and equipment in the construction, forestry, agriculture, cleaning, and transportation fields. As an ISO 9001:2015 certified company, we demonstrate quality daily. We recently expanded our hose manufacturing facility by 20,000 sq. ft. and invested in new extrusion equipment, which is the most advanced thermoplastic hose extrusion process in the U.S. Currently, we assemble over 2.5 million hose assemblies and extrude over 45 million feet of hose per year.

Recent Blog Posts by ProPulse:

ProPulse Receives Bronze EcoVadis Certification

ProPulse is proud to receive the Bronze Sustainability rating from EcoVadis for the second year in a row. What is EcoVadis? EcoVadis is the world’s

ProPulse Achieves Key Supplier Status with John Deere

ProPulse is proud to announce the achievement of Key Supplier Status from John Deere. The award confirms ProPulse’s strategic role in John Deere’s long-term strategy.

Silver Anniversary, Golden Manufacturer

Twenty-five years ago, Schieffer Co. International opened in Peosta with just six employees in a 12,000-square-foot facility. In the two and a half decades since, the hose manufacturer has changed its name and expanded exponentially. Now known as ProPulse, a Schieffer Company, it employs 130, utilizes 130,000 square feet of space, and is celebrating its silver anniversary in March. “25 years is a long time,” said Jeff Theis, President and CEO of ProPulse, “but I believe ‘blink of an eye’ is appropriate when describing our journey.”