It is becoming all too common. Rubber hydraulic hose suppliers not delivering on your order, creating issues in your manufacturing process, and leading to line-down conditions. Continued price increases on your hydraulic hoses are only causing stress within your organization and your bottom line.

The state of the supply chain is very complicated right now, and you don’t need to be worrying about your hydraulic hose supply.

Rubber isn’t the only option when it comes to hydraulic hoses.

Thermoplastic Hydraulic Hose – Rubber’s Younger, Cooler Brother

Rubber hydraulic hoses have not changed much in the last 90 years. It utilizes the same technology, product, and manufacturing techniques. Thermoplastic hydraulic hoses are a better option for agricultural and construction OEMs. Thermoplastic is a more advanced version of hydraulic hose, and in many applications, looks and feels like rubber!

Imagine a rubber hydraulic hose as a bread tie. The more the hose is twisted, flexed, and relaxed the more run down the wire (steel braid) gets. After a while, the wire breaks on the bread tie. This is similar to the steel braid reinforcement on a rubber hose; the steel braid gets worn down in places and breaks, causing a shortened life.

Even with repeated bending motion, the fibers in a thermoplastic hose will not weaken or crack like a wire braided rubber hose. This proves highly effective in flexing applications since thermoplastic can just continue to flex and power forward without fail. Tight routing applications can benefit from a more flexible hose.

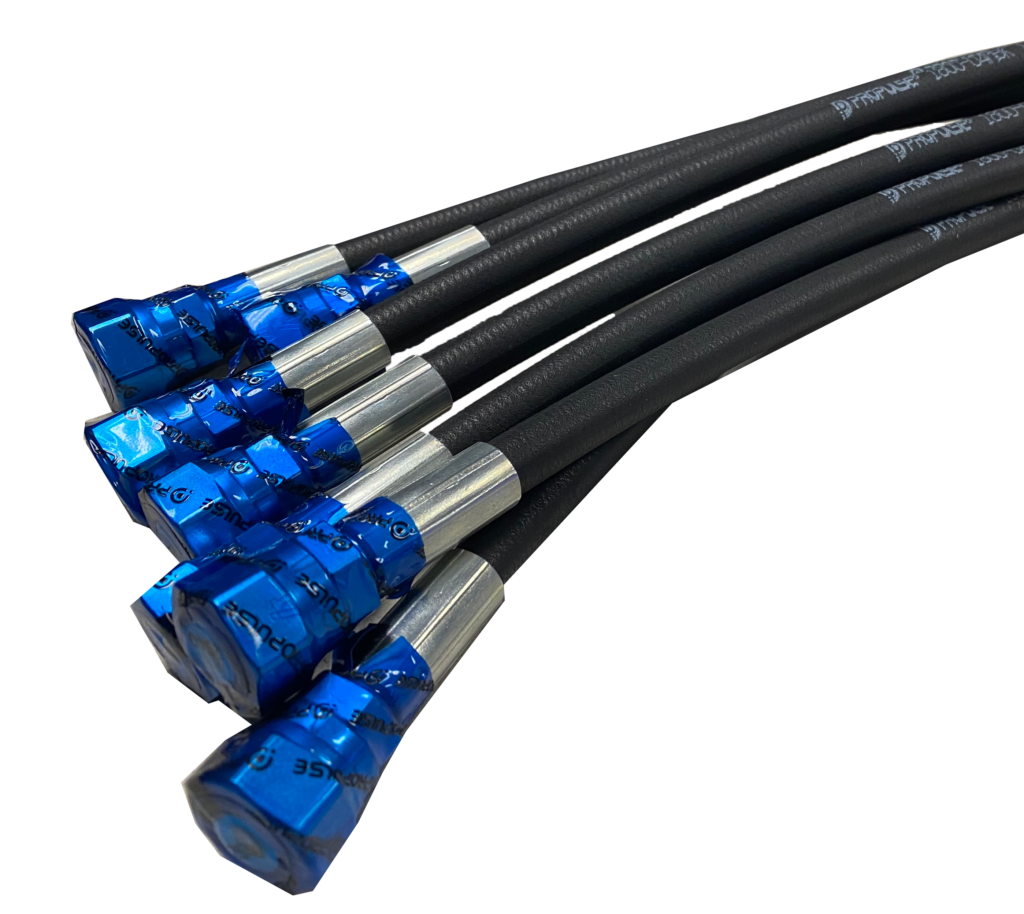

Thermoplastic also allows for the hose to be completely customizable, in terms of color and layline. Unlike your old rubber hydraulic black hose. Hose manufacturers like ProPulse are able to work within your specifications to design the perfect hydraulic hose for your application.

Thermoplastic offers many benefits over rubber, including extreme flexibility, UV resistance, and durability; not to mention cost savings. Don’t get stuck with the same old rubber hose when you can hang out with its younger, cooler brother.

Industry Leading Hydraulic Hose

Immediate Cost Savings

Thermoplastic often comes at a cost saving compared to rubber hydraulic hoses.

Dependable Supply Chain

While other suppliers may have issues sourcing their products from overseas, we manufacture all of our thermoplastic hoses at our Peosta, Iowa facility and have the capacity to meet your requirements.

100% On-Time Delivery

With ProPulse, you'll have one less thing to worry about. We have maintained a 99.99% on-time delivery rate for 3 years in a row. That kind of consistency doesn't just happen, we make it happen.

Custom Engineering

At ProPulse, you get custom engineering options for your hose needs. Our team of engineers will work with you to ensure you are getting the right hose for your application.

In-House Assembly

ProPulse also provides in-house hose assembly. Because of our vertically integrated manufacturing process, we are able to keep costs low while maintaining quality and efficiency.

Zero Quality Issues

As an ISO 9001:2015 certified company, we value quality in all of our processes. We ensure that our thermoplastic hydraulic hoses can withstand the toughest environmental stresses. That's why our products are tested in-house to ensure controlled performance.

Custom Thermoplastic Hydraulic Hoses from ProPulse

ProPulse can custom-tailor performance characteristics such as flexibility, kink resistance, cleanliness, and weight. We can also customize visual characteristics including customized lay lines/branding and color matching.

ProPulse is an Iowa-based hose manufacturer that assembles thermoplastic and wire braided rubber pressure washer and hydraulic hose assemblies. Founded in 1998, ProPulse specializes in supplying OEM production lines for world class companies that manufacture machinery and equipment in the construction, forestry, agriculture, cleaning, and transportation fields. As an ISO 9001:2015 certified company, we demonstrate quality daily. We recently expanded our hose manufacturing facility by 20,000 sq. ft. and invested in new extrusion equipment, which is the most advanced thermoplastic hose extrusion process in the U.S. Currently, we assemble over 2.5 million hose assemblies and extrude over 45 million feet of hose per year.

Recent Blog Posts by ProPulse:

ProPulse Receives Bronze EcoVadis Certification

ProPulse is proud to receive the Bronze Sustainability rating from EcoVadis for the second year in a row. What is EcoVadis? EcoVadis is the world’s

ProPulse Achieves Key Supplier Status with John Deere

ProPulse is proud to announce the achievement of Key Supplier Status from John Deere. The award confirms ProPulse’s strategic role in John Deere’s long-term strategy.

Silver Anniversary, Golden Manufacturer

Twenty-five years ago, Schieffer Co. International opened in Peosta with just six employees in a 12,000-square-foot facility. In the two and a half decades since, the hose manufacturer has changed its name and expanded exponentially. Now known as ProPulse, a Schieffer Company, it employs 130, utilizes 130,000 square feet of space, and is celebrating its silver anniversary in March. “25 years is a long time,” said Jeff Theis, President and CEO of ProPulse, “but I believe ‘blink of an eye’ is appropriate when describing our journey.”